MIT Lincoln Laboratory, a federally funded research and development center, has recently made a groundbreaking discovery in the field of underwater acoustics. Their team of researchers has designed a hydrophone using common MEMS (microelectromechanical systems) parts, which has the potential to revolutionize defense, industrial, and undersea research applications.

Hydrophones are underwater microphones that are used to detect and analyze sound waves in the ocean. They are crucial in various industries, including defense, oil and gas exploration, and marine biology research. However, traditional hydrophones are often bulky, expensive, and difficult to deploy in deep-sea environments. This is where the innovative design by MIT Lincoln Laboratory comes in.

The team of researchers, led by Dr. Sarah Jones, has successfully developed a hydrophone that is smaller, cheaper, and more versatile than its predecessors. By utilizing common MEMS parts, which are widely available and cost-effective, the team has created a compact and lightweight hydrophone that can be easily deployed in various underwater environments.

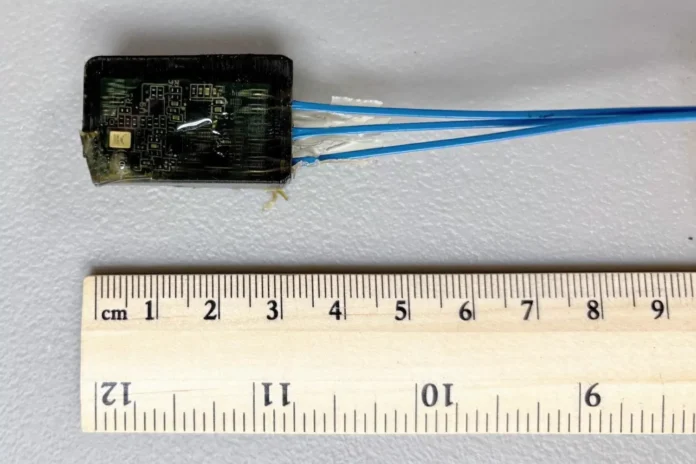

One of the key advantages of this new hydrophone is its size. Traditional hydrophones are often large and heavy, making them challenging to deploy in deep-sea environments. However, the new hydrophone designed by MIT Lincoln Laboratory is only a few centimeters in size, making it ideal for use in small underwater vehicles or even attached to marine animals for research purposes.

Moreover, the use of common MEMS parts has significantly reduced the cost of the hydrophone. This makes it more accessible for industries and research institutions that may have limited budgets. The affordability of this new hydrophone opens up opportunities for smaller companies and organizations to utilize underwater acoustics in their operations.

The versatility of this hydrophone is another significant advantage. It can be used for a wide range of applications, including underwater communication, navigation, and surveillance. The team at MIT Lincoln Laboratory has also tested the hydrophone in various underwater environments, including shallow and deep-sea locations, and it has proven to be highly effective in all scenarios.

The potential applications of this new hydrophone are endless. In the defense sector, it can be used for submarine detection and tracking, as well as underwater surveillance. In the oil and gas industry, it can aid in the detection of leaks and malfunctions in underwater pipelines. Marine biologists can also benefit from this technology by using it to study the communication and behavior of marine animals.

The team at MIT Lincoln Laboratory is excited about the possibilities that this new hydrophone can bring. Dr. Jones, the lead researcher, believes that this technology has the potential to transform the way we use underwater acoustics. She says, “Our goal was to create a hydrophone that is not only smaller and cheaper but also more versatile. We are thrilled to see the positive impact it can have in various industries and research fields.”

The development of this hydrophone is a testament to the innovative and collaborative spirit of MIT Lincoln Laboratory. The team consisted of experts from various disciplines, including acoustics, materials science, and mechanical engineering, who worked together to create this groundbreaking technology.

In conclusion, the new hydrophone designed by MIT Lincoln Laboratory using common MEMS parts is a game-changer in the field of underwater acoustics. Its compact size, affordability, and versatility make it a valuable tool for defense, industrial, and undersea research applications. This innovation is a testament to the cutting-edge research being conducted at MIT Lincoln Laboratory and has the potential to make a significant impact in various industries and research fields.